Bulent Basol on Photovoltaic Solar Energy

Photovoltaics (PV) is the direct conversion of solar energy to electricity employing PV modules. Work on solar cells, which are the building blocks of PV modules, started in 1880’s and yielded practical devices in early 1950’s. Once primarily employed in space, terrestrial use of PV modules gradually increased after government-sponsored research programs were initiated during early 70’s with the goals of increasing the light-to-electricity conversion efficiency and reducing the cost/W. These applications however stayed relatively small in the overall electrical power generation market, annual PV module installations reaching only about 0.3 GW in year 2000.

Golden years of PV, in terms of its deployment, started in 2004 when the German government announced attractive incentives for solar installations. With other countries following suit the global annual PV market grew from about 1.4GW in 2005 to about 51GW in 2015. For those who still doubt the expected prominent role of PV in the future energy picture, I would like to cite some current statistics. The cumulative PV installation in the world was about 235GW in 2015, providing over 1TW-hr of electricity every single day. Photovoltaics provided 7% of Germany’s total electricity need in 2015. Solar energy technologies employ millions of people worldwide, over 200,000 in the U.S. alone.

Commercial solar cells are manufactured using silicon (Si), III-V compounds (GaAs related materials) and thin film compounds (CdTe and CuInGa-Sulfo-Selenides or CIGS). III-V compound based devices are typically used in space applications and in high concentration (300-1000X) systems, which are deployed in “niche” market segments. It should be noted that concentrator PV (CPV) technology, although very efficient (module efficiencies above 38% demonstrated), constituted only about 0.15% of the total installed PV in 2015. CPV is suitable for only utility scale applications and only in geographic locations where direct sunlight is available throughout the year. Silicon based technologies dominate the PV market with about 93% of the PV modules employing either single or poly crystalline Si solar cells. The conversion efficiency of Si modules is in the range of 16-21%.

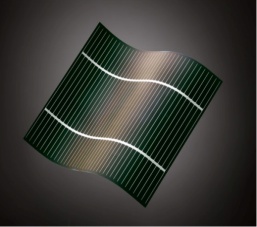

My involvement with PV goes back to 80’s and 90’s when I was one of the few researchers developing thin film PV materials (CdTe [1] and CIGS [2]). In those days Si was expensive and thin film technologies were considered to be the best candidates for manufacturing low cost PV. However, with ever increasing Chinese investment, Si cost has been reduced and the Si PV module prices have gone down from over $4/W in 2000 to about $0.50/W today. As a result, the previously predicted thin film domination of the PV market did not materialize, the market share of thin film staying in the range of 7-15% during the last decade. Nevertheless, technological advancements in thin film R&D have been phenomenal. Today there is about 3GW of annual production of CdTe modules with a module integration process based on an approach developed by our group [3]. CIGS manufacturing is at 1GW/year level. Although, most of the CIGS modules are fabricated using vacuum deposition of films over glass substrates, flexible modules on metallic foils deposited by vacuum approaches or electrodeposition [4] are also manufactured. Commercial thin film module efficiencies are in the 14-17% range, with small area laboratory solar cell efficiencies of about 22%. Considering the fact that poly Si champion efficiency is also in the 21% range, these are excellent results for thin film technologies. However, to overcome the market forces behind the established Si technologies, thin film module efficiencies need to be increased to the 17-20% range. New thin film materials, such as perovskites, that recently showed over 21% lab efficiency are candidates for even lower cost PV once their manufacturing is optimized and the stability issues are understood and resolved.

[1] B. Basol “Processing high efficiency CdTe solar cells,” Int. J. Solar Energy, 1992, vol. 12, pp. 25-35.

[2] B. Basol, “Low cost techniques for the preparation of CIGS absorber layers,” Thin Solid Films, 2000, vol. 361-362, pp. 514-519.

[3] B. Basol and B. McCandless, “Brief review of CdTe based PV technologies,” J. Photonics for Energy, 2014, vol. 4(1), p. 040996-1.

[4] B. Basol, “Application of electrochemical deposition techniques to thin film solar cell processing,” Proc. SPIE, 2011, vol. 8110, p. 81100Q-1.

BULENT BASOL SHORT BIO

Dr. Bulent Basol has more than 35 years of experience in the fields of PV and semiconductors. He started his career at Monosolar Inc., where he developed a high-efficiency CdTe PV technology, which was sold to BP in1984. This technology yielded the highest-efficiency thin-film PV modules at that time. Subsequently, Bulent co-founded ISET Inc. where he innovated both vacuum- and non-vacuum–based techniques for CdTe and CIGS-based thin-film solar cell fabrication, which yielded the first efficient CIGS device produced by a nano-ink–based approach and the first flexible, high–power-density CIGS cell on a polymeric substrate, for which he received an innovation award from NASA. In the 2000-2005 period, Bulent led the research efforts to develop electrochemical processes and tools for integrated circuit manufacturing at NuTool Inc. After the sale of the technology Bulent co-founded SoloPower Inc. in 2005 and Encore Solar Inc. in 2010, to develop electrodeposition-based CIGS and CdTe solar cell technologies, respectively. At the present time he is involved with the development of a metrology technique for ultra thin semiconductor layers employed in advanced transistor structures.