Turkish Scientist Creates Adhesive Nano Structures

Gecko feet have long been a source of inspiration to scientists striving to make superstrong, reusable adhesives. Now researchers at Carnegie Mellon University have found a new way to make such an adhesive grip and release as required, using angled microstructures. These structures mimic the tips of the hairs found on gecko toes, which give the lizard its prowess as a climber.

Gecko-like adhesives have already shown promise as a bonding agent for surgical applications. Some researchers believe that the gecko's special ability could also hold the key to creating reliable climbing robots for reconnaissance missions and space exploration.

Gecko-like adhesives have already shown promise as a bonding agent for surgical applications. Some researchers believe that the gecko's special ability could also hold the key to creating reliable climbing robots for reconnaissance missions and space exploration.

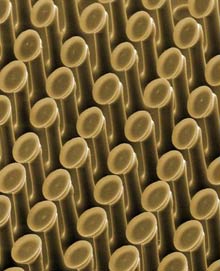

A gecko's toes have millions of very small hairs packed closely together. At the end of each hair are hundreds of tiny, saucer-like structures, called spatula. Weak forces of attraction, known as van der Waals forces, hold each spatula to the surface of the object that a gecko tries to climb. When the forces from millions of spatula work together, they create a powerful bond that lets a gecko stick to nearly anything--even upside down.

Back in 2006, the team, led by Metin Sitti, a member of TASSA and an assistant professor of mechanical engineering at Carnegie Mellon, developed flat, mushroom-shaped tips that mimic the spatula. The tips were able to achieve the same sticking force as a gecko, but there was no easy way to get these tips to release their grip. The team later realized that the key to controlling stickiness lay in changing the angle of the spatula. So Sitti's team took the tips and placed them on top of polymer fibers, angling them at approximately 28 degrees to mimic the angle between a gecko hair and a spatula. As pressure is applied in the direction of the angled fibers, the contact area between each spatula and the object increases, upping the sticking power. Tugging in the opposite direction reduces the contact area and makes the forces of attraction decrease, so that gecko tape, as Sitti calls it, can be released. The group's adhesive was able to hold a one-kilogram weight when pressure was applied in the direction of the angled fibers. A 300-gram weight pulling in the opposite direction was enough to release the tape's grip. The researchers detailed their results in a recent issue of Small.

The adhesive will "enable more robust and power-efficient climbing robots and capsule robots," says Sitti, who develops both in his lab.

Other researchers have been able to achieve sticking power far greater than a gecko's using carbon nanotubes. While stiffer nanotube fibers can strongly hold on to a wall, they have a harder time hanging from a ceiling, says Sitti, adding that his adhesive was able to hold 500 grams from the ceiling. Another major advantage of the polymer fibers used by Sitti is that "they are easily scalable in manufacturing, and cost effective," he says.

Sitti is now commercializing these angled polymer fibers for use in sporting equipment and skin adhesives through his startup, nanoGriptech.

"The design on the tip is interesting," says Liming Dai, a professor of materials engineering at the University of Dayton, who used carbon nanotubes to achieve a force 10 times stronger than gecko feet. "The one thing with polymers is, you can easily make it in nanofabrications for the tip. Also, it's cheap."

"This is clearly innovative work," says Jeffrey Karp, a bioengineer in the Harvard-MIT Division of Health Sciences, who created one-time-use, safe medical gecko tape. "It will be interesting to see if this process can be scaled for industrial applications, or if the adhesives perform better under wet conditions--a major limitation for many of the gecko-mimicking adhesives."

Adapted from Technology Review, January 2009.